This

technique is seldom used with braille scale models, but once you start

superdetailing or scratchbuilding models, it certainly can have it

uses.

Soldering

is an excellent way of obtaining strong joints between metal parts,

especially those connections that are impossible to achieve (or could

never be as strong) with glue. However, there are a numbers of disadvantages,

the biggest of them being the fact that it must be done before the

metal parts are glued onto the plastic model (which would inevitable

melt!), which makes good planning necessary. |

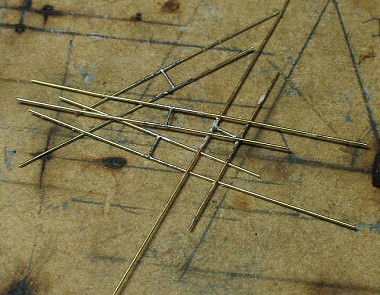

Here

you see a number of examples, some parts which I made using solder

and heat, in scales ranging from 1/35 to 1/72. |

|

As an

example, I'll make a construction using some thin copper or brass

wire. This is available in several thickness; for Braille models,

I mostly use all sizes between 0,2 en 1 mm |

|

These

wires are invariable sold in coiled form.

To make it easier to straighten them, is it imperative to heat the

wire above a flame until it's glowing red and then submerge it immediately

in some cold water. This technique takes away the stiffness out of

the metal, making it easier to bend or straighten. Once your piece

of wire has cooled down, put it on a cutting mat and, using soft pressure,

drag a steel ruler over it back and forth until it is completely straight. |

|

What

do you need next, besides a good soldering iron (I use a simple

30 Watt iron with a sharp point) ?

|

|

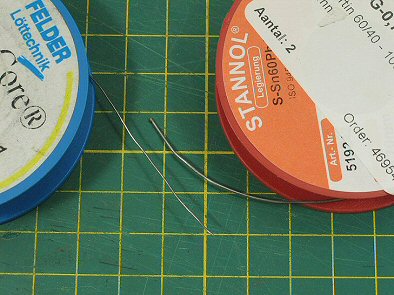

Some

soldering tin, "flux" acid paste (available as solder

fat or liquid) and Pritt Multi Fix (which is a European variant

of Blue Tack).

|

|

DIY

shops sell different types of soldering tin, ...

|

|

...

but I always look for the finest wire available (my favorite is

0.5mm thick, composed of a 60%tin/40%lead alloy).

|

|

You

also need a small wooden block, a couple of toothpicks and clothespins

to protect hands and table against the heat. I adapt the ends of the

clothespins by cutting of some wood to obtain a better grip.

Most soldering is done in two dimensions, however, should I have to

make a three dimensional connection using some wooden profiles glued

on my wooden block can make it easier to hold the lose pieces in place.

|

|

To

demonstrate my method, I'll solder a vehicle light support, connecting

three wires into a letter "H" Before starting, a word of

caution, a soldering iron is hot (200 to 300° C, 400 to 570°

F), so use it wisely!

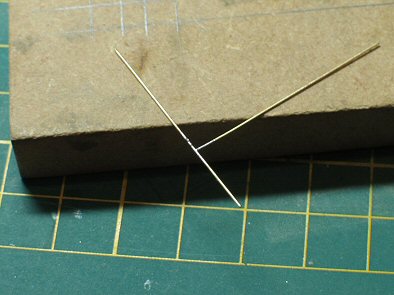

The first

tip I'd like to share with you : if possible, always cut your brass

or copper wire longer than needed! This makes it easier to emplace

the (often very small) pieces in the correct angle or position before

adding the solder, making your end product much better. |

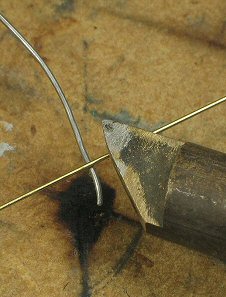

If

feasible, you should always "pre-tin" your wire by melting

a thin coat of tin on the connecting points. This will make the soldered

joint stronger. How to proceed? First, put a bit of flux on your wire,

... |

|

... then

bring the wire in contact with the solder. Next, let the preheated

iron touch the wire, as closely to the solder, but not into it.

|

|

The

soldering iron should heat the wire until the latter reaches the melting

temperature to make the tin flow and fix itself onto the greased wire.

A mistake commonly made is to touch the tin with the iron,

thereby melting the tin but without the wire having the desired temperature

which will result in a weaker joint.

Remember

: liquid tin has a beautiful shine, cold tin is matt.

As soon

as the wire has a nice coat of tin, gently remove the iron from it,

which will make the tin turn matt. Repeat this with the other wires,

the result should look like this : |

|

Once

all the wires properly tinned, we can proceed with the next step.

Using the Blue Tack, both wires are immobilized in the correct position

on the wooden block. |

|

Apply

a bit of flux where the joint should come. Once again, let the soldering

iron touch one to the wires as close as possible to the fat (but not

in it); After a few seconds, the tin present on both wires will become

liquid and merge on the greased connection. Taking away the iron will

harden the solder.

Check the result and if satisfying, carefully start removing the Blue

Tack. Should this putty be difficult to remove, by gently pressing

another small ball of Blue Tack onto it, the remaining stuff should

come loose. Always try to avoid exercising strong pressure on the

joint, e.g. when filing away some surplus solder.

|

|

Now

we can start connecting the third wire. Cut the perpendicular wire

to the desired length. Pre-tinning the remaining short end is impossible,

because the heat could also dissolve the connection we’d just

made. The new wire however will get this treatment.

Once again, immobilise everything in the desired position on the wooden

block using Blue Tack. Also put a bit of putty on the previously connection

made; this will drain some heat away from these wires, preventing

that connection to come loose.

However,

make sure your iron will have free access to the third wire.

|

|

Next,

follow the same procedure : apply grease to the new joint and let

the iron shortly touch the third wire until the tin connects with

the short wire.

Remove

the soldering bolt and inspect the result. If OK, remove the surplus

tin with a metal file or abrasive paper. Take care not to remove the

tin in the joint itself, otherwise you’ll have to start all

over again.

Once

the clean-up terminated, you can cut every wire to the correct length. |

|

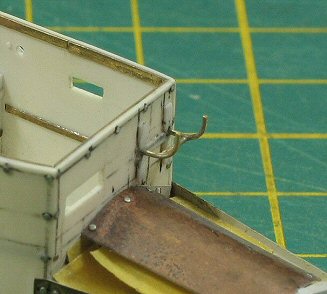

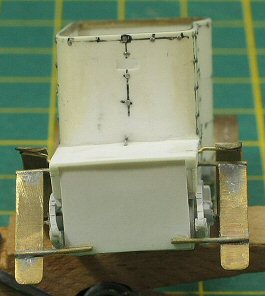

This

image shows the work piece installed on the model, waiting for its

light to be added...

|

|

...

and then with the plastic light glued onto it.

|

|

Another

example of the soldering technique to get stronger mudguards

|

|

One

final tip, soldering goes relatively fast once your iron is hot, so

why not make a couple of work pieces more than needed? Then you can

choose the best one and thus get a better model.

Happy

soldering…

|

|