|

With the release of the Revell Warrior and later the Up Armoured version, there was finally something to go with the Revell Challenger 1 and the later Dragon and Trumpeter Challenger 2 vehicles. Whilst the Revell Warrior is very good in terms of moulding and fit, there are a few details that could be made better. With the unfortunate pass over to new owners of the site some of these pages went missing, the good thing is that in between then and now new information has come to light, so giving me a chance to bring the article right up to date with the latest versions currently deployed in Afghanistan. The aim of this article is to show how to bring the Revell kit up to spec. I will also show some of the various upgrades available from CMSC and PDI Model Supplies, and the Extratech PE set, along with their faults, as well as the faults in the original Revell kit and how to correct these and what needs to be added. I daresay that some are pleased with the Warrior as it is. For those this article is not meant to deride anyone, as it always depends on your area of interest as to what you find acceptable in a model, and the more a model encroaches on your area of interest the more faults you find. For me I find that with WW2 and earlier I am prepared to accept faults easier than with Modern British and Russian vehicles. For others it will be the other way round and there will be those with a completely different point of view. For those that are interested you can incorporate as many, or as few, of the changes as you wish, as some will be time consuming and, for the want of a better word, fiddly. Before proceeding further, please first read my following warning. The more I got into modifying the Warrior

and correcting the major faults the more I started finding things

that were wrong, and to correct all the faults would mean practically

a total rebuild. Of course there are parts of the kit that can be

modified to meet the requirements, but if planning to build more

than one vehicle, the only way is to modify one part and copy

it in resin for the others. At the end you would be left with very little

plastic. What

is wrong with the kit? Well,

actually quite a bit, some of it is due to the molding process (i.e.

to be able to release the model from the mould) and some of it is

due to research errors. There are other parts that are entirely cosmetic

but add to the model as a whole. Moulding process errors 1. Most of

the access hatch hinges on the upper hull are vertical, where as they

should be at 90 degrees to whichever plate they are on. Most noticeable of

these are the front plate hinges and the drivers side plate. 2. The rear

troop compartment hatches have solid hinges, instead of a bar. 3. The rear

troop compartment periscopes have the incorrect profile, as does the one

between the commander and gunner in the turret roof. Research errors (missing

or incorrect details), in no particular order 1. Rear

stowage bins are too short. 2. Left hand side access

panel just behind the driver is too deep. 3. Turret

periscopes are the incorrect shape. 4. Raven

sights for the main gun are incorrect in shape and height. 5. Armoured

deflector for the engine louvers is too small. 6. Smoke

discharges (need I say more?) these seem to be the one thing that

Revell consistently mess up on British vehicles (e.g. Challenger 1). 7. Gun

mantlet too narrow and missing detail. 8. Lip

missing from front of turret. 9. Final

drive housings too wide. 10. Air

intake cowl too shallow. 11. Incorrect

mesh alignment shown on turret and hull baskets. 12. Missing

or poorly depicted smaller lifting eyes on turret and hull. 13.

Incorrectly placed fire extinguisher on the rear door. 14. Incorrectly

shaped roof vent. 15.

Rear door hinges too big. 16.

The hull sides are not deep enough. 17.

Wheels not deep enough. 18.

Final drives too small in depth. Up armoured Warrior As above with

the following additions. 1. Side

armour panels too thin. Also the armour stands too far away from

the hull sides. (Interestingly the stand off distance and the thickness

of the panel would be the correct depth for the real panels, thus

by adding plastic to the rear to cover the rear of the panels, the

correct thickness can be achieved, although, by doing this you will

need to reshape the front and rear portions of the panels, but more

on this later). 2. The front

glacis armour is totally wrong, firstly the top armour block is the wrong

shape and doesn't extend up the glacis far enough. The bottom part is

compounded by the fact that the final drives are too large, this makes

both the front bin and the armour too narrow. 3. No

mounting brackets for the armour depicted. CMSC

Parts 1. The side

armour provided by the CMSC set is the wrong size. The individual panels

are too big (wide) and although the correct number of panels are depicted,

because of the size the right hand side is about 1 complete panel too long. This

pushes the front too far forward on the right hand side, obscuring the drivers view.

The left hand side panel is also too long but not as extreme. Also the individual

panels in each side are all different sizes (whereas most should be the

same size, except for the obvious panels that are of a different shape and

size). Here the Revell kit has the correct size of panel (if not

depth). 2. The

frontal armour, although of the correct size for the top, the lower

armour suffers from the same fate as the Revell kit due to the oversize

of the final drives. Also the frontal armour is at an incorrect

angle and should be at a much sharper angle. 3. No

mounting brackets for the armour depicted. The

Corrections and build Lower

hull The lower

hull can be built as per the instructions, the only thing needed

is to drill out the holes in the sprockets as well as the two holes in the centre track

return roller, both of which will improve the overall look of the vehicle. It would be worth

painting and weathering the track

units at this stage before they are fitted to the hull to provide

easier access to a lot of the running gear. Overall weathering

can be done later once the kit is built, to bring it all together. The

following pictures show weathered wheels and track units before

being attached to the hull. Before attaching the wheels and tracks

drill out the holes in the tub that make the locations for the side

skirts front and rear covers. This will become apparent later as

to why. The first

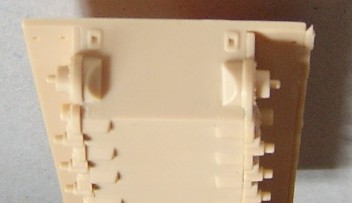

change that needs to be made to the lower hull are the final drives,

which need to be cut down in size. This is a fairly easy process,

done by removing approx. 1mm of plastic from the inner edge of the

final drive housing where they meet the track assembly. This way

none of the detail of the final drive housing will be lost. The

end of the housing should extend along the lower plate as far as

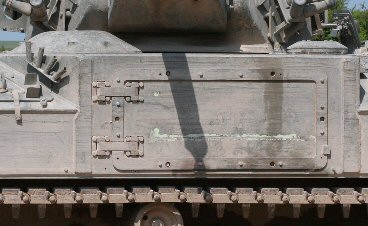

the end of the towing eye mounts. The following pictures show from where

the plastic needs to be removed and how far the drives should

reach. Really the final drives are too small The

towing eye mounts need to be altered, as they need to

extend down to the final drive housing and 8 bolts (4 either side)

need to be added. This only needs to be done to the right hand side if

fitting the front armour. If the armour is not to be added then

the left hand side also needs to be extended and bolts added at the same time. Under

the right hand final drive a piece of plastic needs to be added.

This is presumably part of the first road wheel suspension housing. If

the side skirts are to be fitted, or just the front or rear portions,

the four small rivets need to be added to the edges both on the

front face and on the sides of the front and rear track covers. For

the Bold and the Brave Now

we come to a conundrum. The model's sides are too shallow and the fix unfortunately

it is not as simple as building new sides. The problem not only lies in the depth of the sides,

but also in the track units. The kit tracks are too thin and although

some of the thickness can be made up by attaching new rubber pads

and new longer guide horns, the tracks are also too close to the

hull in more ways than one. The main tub of the kit should be wider

forcing the track units out to be almost inline with the hull sides.

The only way to fix this is to add plastic between the track units

and the tub walls which will need some creativity to hide the fact

at the front and along the bottom, but not so much at the rear, as

there is missing detail which can be added to cover this. (see hull corrections).

The problem lies unfortunately not only in the top hull, although it does

contain the sides, but in the bottom tub and the tracks as well. The distance

between the tracks and the hull is too great and you can't cut down

the track units without it affecting the whole bottom unit as that

would affect the height, and the height of the hull roof is more

or less the correct. So how to fix it To

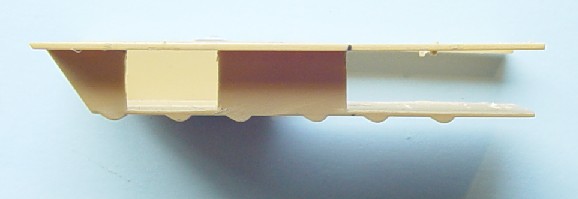

do this you will need 4 strips of plastic, 2 strips need to be 7.5mm

wide, the others 9mm. Both strips need to be 0.5mm thick and 83mm

long. One of each size now needs gluing together, one on top of the

other, so that one side is parallel and the other side forms a lip.

This combined strip then needs gluing to the underside of the sponsons after the

wheels, with or without tracks, have been fitted. This not only reduces the

distance between the hull and the track, but also deepens the hull

top when it is fitted. These measurements should also give a slight

overhang along the side, front and rear, even when the hull top is fitted.

The fix also alters the rear bins and certain other fittings but

also fixes some other problems that would otherwise prove difficult.

But then it also presents other problems that are harder to fix, one of these

being the NBC housing door. As it is in the kit, the housing door is too shallow,

but is not noticeable because of the incorrect hull depth. Correcting

the hull depth will now expose the shallowness of the door. Correcting

the door will require surgery, by cutting the door length wise and

inserting a plastic shim to correct the depth, however most of

the detail will need to be replaced. The door can then be replaced

using the two strengthening strips, as on some models these extend

all the way down, thereby covering any joins. Later

models On

later models without add on armour, there is a noticeable strip

with bolts between the final drive housings used for

the mounting of the add on armour. One thing

to note for the more adventurous of you, is that if you plan to

build an interior, and there are many good photos on the web to

help you achieve this, you will need to remove some plastic from

the hull tub before attaching the track units. This is because the

hull tub takes up internal space, which would make the interior

too narrow. This is one of the problems with the PDI interior. To

try and regain the illusion of space, PDI have made the seats very

narrow, for anyone but a midget to sit on. The following photo show

where the plastic needs to be removed from. The forward portion

is for the driver. |

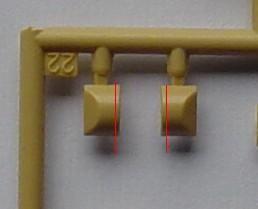

<== Cuts to the final drives

<== Cuts to the final drives <== Position

of Final Drives on the model

<== Position

of Final Drives on the model