1.

Hull

The hull is a one-piece moulding and comes without a floor in order

to allow a screw (included) to be used to fix the turret in position.

I chose instead to blank off the hull bottom with a ½ mm

plastic card floor. A length of plastic rod was then glued into

the hole, at the bottom of the turret, to put it in place on the

hull top and allow it to revolve.

The too thick mudguards were not convincing and were very carefully

cut off using a new sharp blade. A lot of sanding (wet owing to

the resin) was necessary to clean up the sides before putting in

place new mudguards and their supports. They were built from food

aluminium foil, this material being easily obtained, cut and bent

to shape.

Exhausts and their silencer are best replaced with copper wire/plastic

rod of a suitable diameter. Their ends were hollowed out for realism.

Note that AL.BY does not provide any manual or instructions of any

kind, at least not in my specimen.

2. Running gear

Road-wheels look like copies of the old Matchbox Wespe and are rather

under-sized. Moreover 8 out of 10 were suffering from a lack of

material on their outer rim and I decided to replace the whole lot

with Matchbox Wespe roadwheels from my spare-box. On the real thing,

those wheels are identical to their T-70’s counterparts and

they were put to good use on my model.

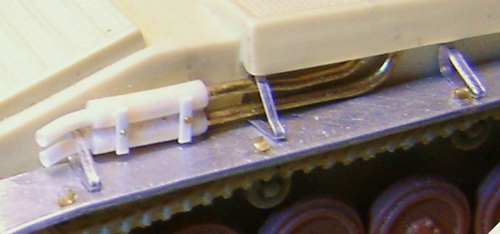

Sprockets and idlers were kept as well as the resin tracks, IMO

also copies of Matchbox Wespe tracks. They were put into hot water

in order to conform to the running gear and take some sagging. They

came in one piece (L&R) and I had to cut them to L&L to

ease assembly. In the process, I broke several pieces that I replaced

with a length of plastic track of similar pattern, found in my spares

box.

3. Turret

This is a s a one-piece moulding too, save for the commander’s

hatch which is separate and must be detailed if used in the open

position. That’s what I did and without much reference on

the subject, I used as a guide the inside of a T-34 turret hatch,

plausible if not 100% accurate.

4. Armament

The gun tube was badly moulded and bent; it was replaced by a piece

of Evergreen rod that had its end drilled out.

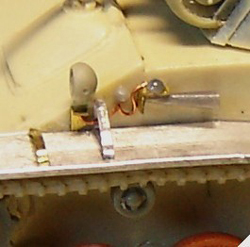

5.Detailing

All lifting eyes, moulded directly on the vehicle , were replaced

with fine copper wire. Other small details omitted by AL.BY like

supports, light cable, horn, were scratch-built from remnants of

a PE fret and/or plastic, super-glued in place at the tip of a fine

needle.

6. Painting and finishing

Brush-painted only, the model was firstly coated with a thin coat

of enamel light grey paint, followed by a light coat of green enamel.

After I had let it to dry thoroughly, the model received several

filters of green and ochre acrylics from Vallejo, mixed-up in different

proportions to give depth to the model and, last but not least,

pastels and graphite powder were used to good effect to bring the

beast to life. Figures are from Preiser, the commander’s head

being from Milicast.

7. References used

-Internet

-Steelmasters hors-série N° 32 Stalingrad Operation Blau

vol.1 (French language)

8. Conclusion

Like all resin kits, this one requires great care in cutting and

sanding parts. Cyanocrylate glue was used throughout assembly. There

are a few small holes to be filled with bits of plastic and superglue,

but nothing that can’t be mastered by the average modeller.

This diminutive tank can be turned into a nice model, provided that

one is willing to improve the basic kit with some replacement and

scratch-built parts. It may be difficult to get, like all AL.BY’s

production. I got mine many years ago from the well-known shop “le

16ème escadron” in Brussels, Belgium (no connection,

just a customer).

|