The

second vehicle of the set is the Standard Motor Company Tilly. I immediately

liked this truck, with its 30’s civilian bonnet. First of all

“Tilly” wasn’t the name of a vehicle but a family

of vehicles. Four different producers made their own Tilly. The Standard

Motor Company was one of them. The Standard Tillies were built in

three series plus an ambulance version and a civilian family saloon

car supplied at the beginning of the war. The type chosen by Airfix

is the 10 cwt DC series, which was allocated only to the Air Ministry.

Some useful photos (then and now) of the DC Tilly can be found here:

http://standard.tillyregister.com/classic.html

The former, narrower 5 cwt BB series was similar.

It can be quickly recognized by the different forward mudguards layout

and the step at the base of the side doors. The later UV series (allocated

also to the Army and the Royal Navy) was quite different, having a

longer wheelbase chassis, vertical windshield, different radiator

mesh, wheels, sides and doors. For the Army Tillies the WD vehicle

class prefix was the letter M (but this is not the case of this kit

model which wasn’t allocated to the Army). For a UV Tilly walkaround

see here: http://www.wheelsofvictory.com/Brit%20index2.html .

About

the DC series production changes, the only evidence I found is about

the lights which became smaller and set farther apart. Sadly I found

only a handful of photos and very little information. What surprised

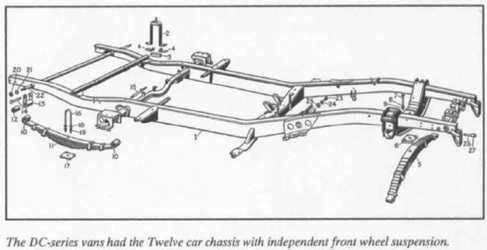

me was that the DC 10 cwt had independent front suspension with a

transversal leaf spring and not the double longitudinal leaf springs

of the kit (see here: http://www.standardmotorclub.org.uk/page780.html).

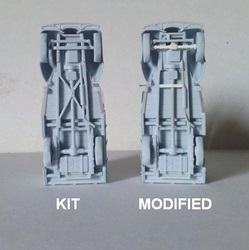

Judging on the basis of the drawings in the article, the Airfix DC

12 hp (10 cwt) kit seemed to have, under a DC body, an UV 14 hp chassis

with the DC wheelbase. I looked for photos of the real structure with

no results. I didn’t find a walkaround on the net and only two

DC are still preserved today. At the end I wrote to the Tilly Register

site. Luckily Michael Shackleton kindly sent me three photos which

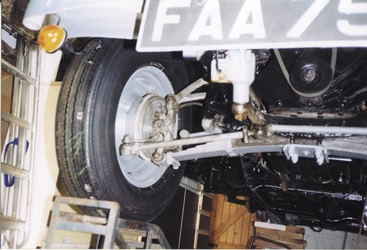

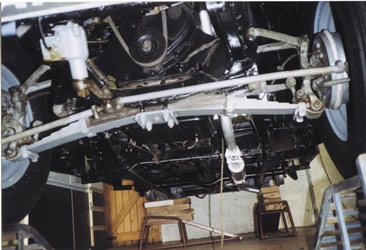

show the front suspension system. It was effectively completely different!

The differences can be described, concisely, as follows: the front

axle was a rod, shaped as a large opened “omega” attached

to the chassis and which embraced the engine belly. At the endings

of the axle, there were two vertical “V” shaped structures.

At the lower single point of this was a hinged rod, at the upper points

were the hinges of the double endings of the wishbone piece. The opposite

rod end and the single end of the wishbone were hinged to the wheel

hub. The wishbone and the single rod could move up and down for the

suspension of the wheel, with the hub attached to them. Attached to

the centre axle bottom there was the transversal leaf spring which

endings are attached to the wheels hubs.

Unfortunately my first Tilly was already made with

the kit chassis, because I found the discrepancy after having glued

it. But I had a second kit…

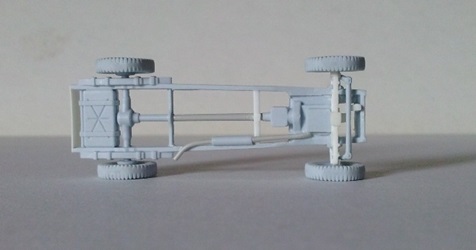

Chassis modification

After having taken the dimension to maintain the same

ground clearance, I removed the axle with the two leaf springs from

the front suspension.

I shortened the engine belly to the axle level and the forward lower

profile of the chassis was filed to the shape shown by the drawing

visible here: http://www.standardmotorclub.org.uk/page780.html.

I removed the “X” structure, the exhaust and the transmission

rod.

The transmission rod was replaced with stretched sprue of the same

diameter...

as well as the exhaust with the thinnest rods available.

A plastic strip was added just after the gear box.

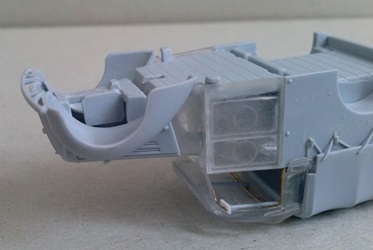

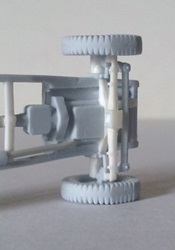

The front suspension structure described above would be a bit fragile

if reproduced correctly. Being partially hidden by the wheels and

the mudguards, I took some licence to have a strong attachment. Following

the photos, a new solid axle was made with plastic. From the front,

the engine was simulated with a thin little plastic piece. To this

I glued a rounded piece of plastic for the lower distribution pulley.

After having glued the wheels, kept together by the steering rod,

a leaf spring from the spare box was attached to the lower side of

the axle. Stretched sprue provided the material for the smaller details.

The steering gear and arm were added to the frame with stretched sprue

and plastic strip.

Looking at the photos, the belly of the vehicle looks filled with

other little details. Both the little scale and the poor visibility

of the details led me to be satisfied with the described job. I didn’t

add anything else and think it now looks more likely the true chassis.

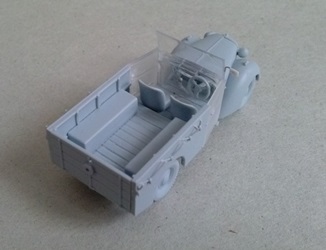

Body

Chassis alteration apart, the kit depicts the Standard

Tilly early DC type well and very little interventions are needed

to improve the model (which dimensions are correct). Also in this

kit some pin ejector marks need to be sanded down here and there.

In my opinion the kit required a minimum of detail. Here is what I

made:

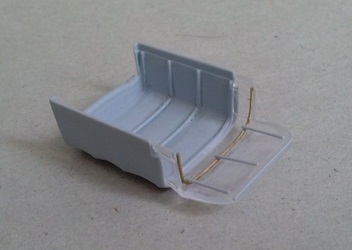

The body

floor is smooth. Based on the photos of the restored vehicle it seems

to be made with wood planks. To engrave their lines I carefully cut

off the wheelhouses and then I engraved the lines. The wheelhouses

were glued in place at the end.

The riveting relief on the sides is oversized and in the photos it

is not visible. I cut it off without sanding it down, to maintain

the hint of it.

Also the items just forward the cover wire hooks are absent in the

photos I used; they were totally erased.

I added the inclined gear shift made with stretched sprue with its

rounded end made by glue drops.

The engine is missing. To avoid a see through effect I glued a plastic

piece into the empty bonnet.

The rear chassis was shortened at the fuel cap position and a plate

made of thin plastic was glued to close it.

As for the Bedford MW, the door windows were made of soft transparent

plastic and I choose to remove them. I replaced the door handles which

are undersized.

The position light on the mudguards received a thin stretched sprue

segment to make the two rounded items in place of two vertical pins.

When the glue was dry I sanded them, trying to obtain a half egg shape.

The fabric cover was composed by two parts. The forward one for the

driver and passenger seats and a rearward for the load area. This

last one overlaps the vehicle sides a bit too much; I filed the edge

to the transparent part level and then I thinned them.

Its inner frame is partially represented. With stretched sprue I added

the upper section of the inverted “U” rods of the rear

part. If this part of the fabric cover is omitted, the frame should

be reproduced. In the area of the forward cover part (made with transparent

plastic in the kit) no frame is present at all. Having removed the

windows, the inside is visible, so I made the visible rods using both

metallic wire and stretched sprue.

The fabric cover edges need the wire which kept it stretched going

up and down from the body sides hooks; I made it with thin stretched

sprue as well as their hooks on the truck sides, following a common

alternation sequence.

The rear view mirror was made with metallic wire (because the support

was curved) and a little plastic rectangle. The whole was carefully

glued on the windshield frame to avoid the “frost” effect

on the transparent part.

Conclusion

Chassis problem apart, in my opinion the kit is well

done and looks very nice. If placed on a base or when parked on the

shelf, the problem is barely visible. This vehicle series was used

only by the RAF and can’t be used otherwise. It will look very

well placed near a plane on an airfield background or on a dispersal

field. In 1944 the RAF followed the troops in France. I don’t

know if some Standard Tilly went there with the planes, but if so

that is another background to place it.

A particular thanks goes to Michael Shackleton of

the Tilly Register for its courtesy and the permission to use its

photos in this review.

|