|

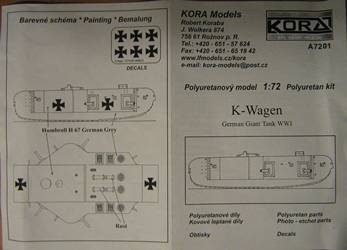

Material:

Resin & Photo-Etch

Quality:

Detail is a bit soft and the photo-etch is used for some surface

details. Large plugs/runners of resin need to be carefully removed

from all the parts.

Parts:

Resin (46); Photo-Etch (25).

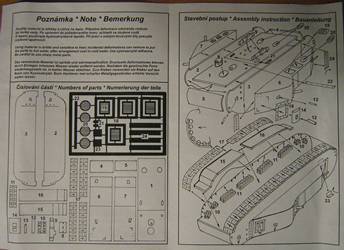

Instructions:

Exploded diagram, parts numbering and paint/decals scheme.

Packaging:

Cardboard box and heat-sealed plastic bags.

Additional:

The front hull plate is lacking the following:

1. driver's vision slit,

2. front gunner's firing hole with vision slit

3. front gunner's MG.

The commander's cupola hatch is molded

shut, and there are no crew doors molded on the sponsons. The hull

bottom is a true problem. You have to carefully glue the bogies

to the inside of the hull that has a taper to it, and they are only

held on by one side. The hull bottom plate comes in 2 pieces and

is not wide enough to touch each bogie's inside. Also there are

no supports for any of these pieces, no locating holes, no tabs,

nothing, only a very finely scratched line to help align the bogies.

Decals are included, but since the K-Wagen was a 'late war' panzer,

the Germans were beginning to use the "Balken" Cross on

their tanks in 1918, so the "Maltese Cross" is probably

wrong for this. The color scheme is also incorrect. There is no

verification that the Germans were using this shade of gray in WW1.

This is the first kit of the German

WW1 K-Wagen in any scale.

BUILD

I am excited to have this resin kit in my arsenal. However, it is

not for beginners! You need a lot of time for sawing and sanding

the resin plugs and runners from the kit pieces. In addition, I

advise many, many dry-fit runs before gluing it together. I hope

that my photos and notes will help someone to avoid the same mistakes

that I made with this kit. In the end, I am sure we will enjoy the

resulting K-Wagen!

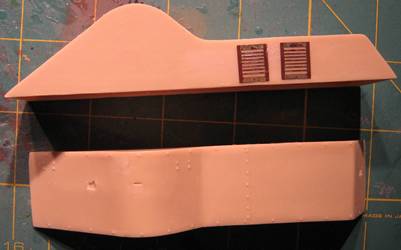

Sub-Assembly 1: Sponsons

Above Photo: these are the left and right sponsons which

hold the armament (cannon and MG as well as the gunners, ammo, etc).

As you can see there are no doors to get into the sponsons! You

will have to scratch build the doors.

Each sponson has a dimple on the top just forward of where the PE

vents go. I saw no reason for the dimples, so I filled them in.

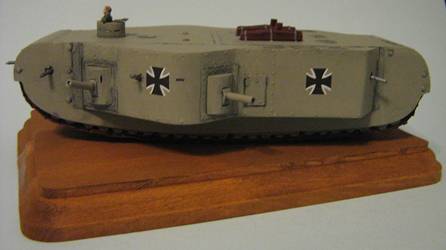

Above Photo: (finished model) I have scratch built doors for

each sponson .

Sub-Assembly 2: Hull / Sponsons

Left Photo: I wanted to open

up the cupola to place a half-figure into it to help show the vehicle's

size. I used my Dremel tool and a router to bore the hole into the

cupola (this will later receive a half-figure). I added the photo-etch

details pieces, exhausts and cupola to the hull top and glued the

hull sides on at this time.

Right Photo: Scratch-built hatch with handle, hinge bolts

and locking mechanism. As you can see, I have large gaps between

the sponsons and the hull sides. This is due to the inside molded

'guide' for the side pieces. I didn't catch it when I glued the

hull sides on, they became uneven at the front, and so I sanded

the front left and right hull tops to blend to the hull sides. When

I placed the sponsons on, I realized my error! I suggest that you

glue the sponsons on to each hull side first, this will give you

a much better alignment and less filling to be done later.

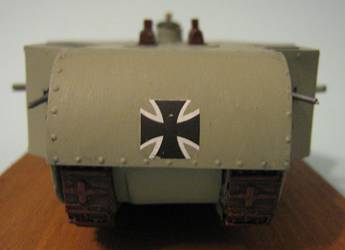

Sub-Assembly 3: Cupola and Front MG Port

Left Photo: Close-up of the half figure (from the spares

box) and the scratch-built hatch.

Right Photo: The hull front plate is lacking a driver's

vision slit and gunners MG opening, so I drilled them out. The gunner's

slot will be cleaned up better (I made it too large).

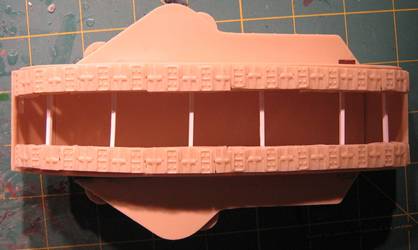

Sub-Assembly 4: Hull Bottom

/ Track Assembly

Left Photo: This is the real

problem area. Kora does not provide a proper hull bottom plate;

instead you get all the bogies and 2 hull bottom pieces, very little

alignment marks. On top of that, the hull bottom pieces are not

wide enough to hold them all together! I decided to use styrene

rods to help strengthen the kit, but more importantly, to give a

platform for the bogies and hull bottom plate to align with and

glue to.

Right Photo: Bogies and tracks in place.

|