To

field as many 17pdr armed Fireflies as possible, the British also

used the M4 “Composite hull” (which they called “hybrid”)

in addition to the Sherman Mk I and Mk V. At the time of writing,

the M4 Composite hull/Sherman Mk I Hybrid is not available as a 1/72

plastic kit. There are two options to get one: the first is joining

a cast hull front from a M4A1 76mm to a M4 kit. The second is using

a resin conversion set. I was considering the first one when a friend

donated me the MR Modellbau conversion kit.

The set is designed for the Italeri M4A1 kit. This seems to be a strange

choice to me, because there are better kits to use as a starting point.

In theory, every M4 and M4A1 has the correct lower hull. However,

always better to check the details: this particular Italeri kit has

the correct belly maintenance plates for a M4A2 or a M10.

The resin set is composed by an upper hull with a turret, a set of

14 open spoke wheels, a pointed cast transmission cover and smaller

resin pieces such as bins, smoke dischargers, fenders, exhausts, air

filters, grouser storing cover, a telephone box, muzzle brake, turret

bin and the new idler supports. In my kit, the mantlet was the standard

M34A1 one and not the Firefly version. I’ve checked the photo

of that item on the MR Modellbau site and found the mantlet to be

correct, so I think my problem was due to a packaging mistake.

Other little parts are made in metal: sprockets, hull hatches, air

intake cover, idler pins and the track tensioner tool.

There

are also some surplus parts: a US type all around vision cupola hatch,

a US type loader oval hatch, a MG support and two little items. Unfortunately,

some pieces were also missing: the gun cleaning rods, spring towing

device and its hook, a fire extinguisher and a resin piece which is

listed as “25 - stowage and gear” but not shown in the

instructions.

The details look well done. The hull cast front is well depicted,

better than another conversion set I’ve seen.

My (usual) first step is identifying the variant proposed. The M4

Composite hull was built by both Chrysler and ALCO. It was the last

75mm armed M4 type produced and arrived on the production line in

the second half of the 1943 (August for Chrysler and October for ALCO).

Ignoring the very first tanks produced, the early Composite hull had

the "no pistol port low bustle turret" while the later ones

had the high bustle turret with the oval loader hatch. There also

were some differences between the two plants. From a 1/72 perspective

I think one can ignore the smaller ones, but he has to pay attention

to the more obvious differences :

- Chrysler:

rear towing hook absent, sprockets wheels with spokes, notched sandshields

supports, right forward appliqué armour with clipped corner.

- ALCO:

rear towing hook present, sprockets wheels without spokes, notch

less sandshields supports, right forward appliqué armour

with rounded corner.

Both

versions were randomly mixed in the batches T261894 - T263893 and

T269094 - T271093, although in my photos, I have seen Hybrids only

with 263xxx and 269xxx numbers.

The tank proposed in the conversion kit is a Chrysler. The resin hull

doesn’t have the sand skirts support strips.

Although at first glance, the resin parts look well made with crisp

small details, a closer observation revealed air bubbles, resin excrescence

and two serious errors: the hull dimensions and the turret layout

and alignment.

As usual,

I wanted to depict a Normandy campaign tank. I used the Hunnicut book

and this very good website http://the.shadock.free.fr/sherman_minutia/index.html.

Here

is what I did : |

Turret

The turret depicts a high bustle turret, so it has the pistol

port (correct), but it doesn’t have the cast-in armour (not

correct). This turret type was effectively used for the Firefly

but, having already its own loader hatch, as far as I know, this

was retained without modification (see photo #1).

If the kit turret is used as a high bustle type, the hatch must

be changed and the lower bustle edge needs to be rounded (the

turret one, not the radio box).

If the turret is converted in a low bustle type, the hatch has

to be retained. Luckily I had a spare radio box, so I could convert

the turret in a low bustle type because the photo of the tank

I’m trying to depict had it.

|

|

I

say “luckily” because I had however to remove the radio

box and rework the turret, because my resin turret was cast obliquely

oval.

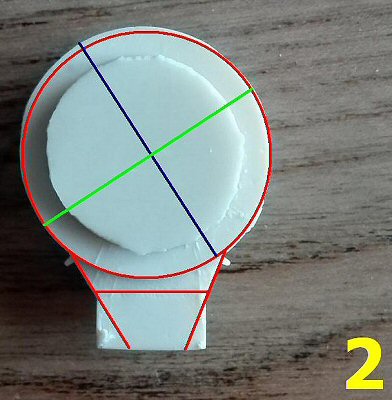

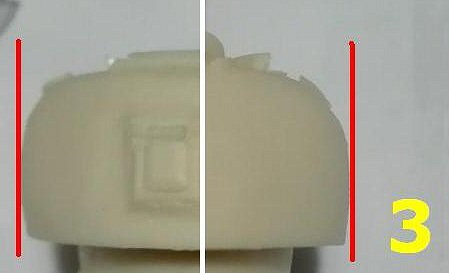

In photo #2 I show a red circle to enhance the general oval form; just

check the longest diameter the blue line) against the shorter one (the

green line).

The bustle also resulted asymmetrical.

|

|

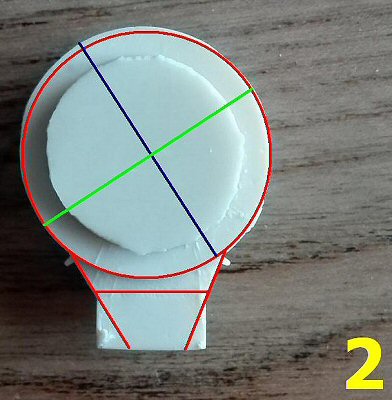

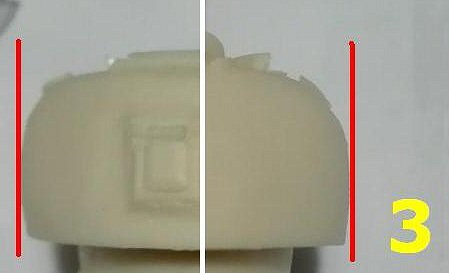

| Furthermore

the forward half of my turret had bulging sides, not vertical ones (see

photo #3). Anyway this could be a “una tantum” problem not

shared by every turret cast by MR Modellbau. |

|

- A

careful filling and filing job was needed to restore the rounded

shape, to get the left forward side vertical and to shape the cast-in

armour on the right forward side.

- The

interlock, which goes in the upper hull hole, was also made more

round, adding plastic where needed.

- I

removed the pistol port.

- I

removed the radio box and then I reshaped the bustle adding plastic

on the bottom.

- I

replaced the lifting points with metallic wire.

- The

cast on gun mount is the late M34A1 type without the lateral flange

and needed a bit working of the sides, which weren’t parallel

when seen from above.

- Due

the packaging mistake mentioned above, I had to replace the standard

M43A1 mantlet supplied by MR. Luckily I had a UM spare part, so

I used it as a replacement.

- Since

I removed to the original radio box to change the bustle layout,

I added a UM radio box from my spare box.

- The

loader hatch received its stop made by thin plastic sheet.

- The

squared bracket behind the hatch (removed during the bustle reshaping)

was made in plastic.

- The

aiming device was made with a shaped staple.

- The

turret bin (34) was sometimes attached to the radio bustle. This

gave a strange stretched silhouette to the turret (in my opinion).

I didn’t use it, anyway if used it should be shimmed because,

being correct in height and width, it is a couple of millimetres

short in depth.

- I

added an interlock made by plastic sprue to the turret to avoid

it accidental falling out of the hull.

|

|

MR

Upper hull

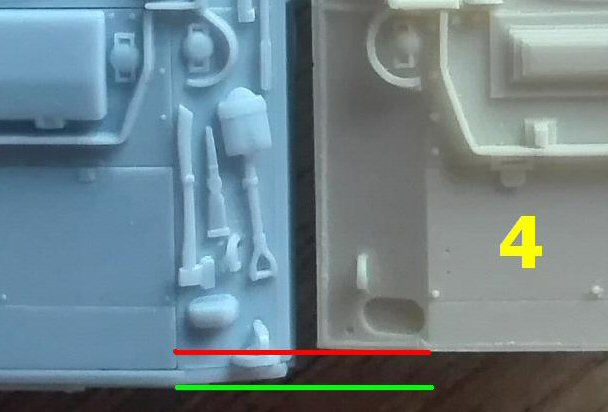

Comparing

the hull with both photos and drawings revealed the upper hull being

too short in length and height. The length shortage is in the engine

compartment and is made very visible by the two oval holes which are

almost attached to the rear plate, a simple comparison shows this isn’t

correct (see photo # 4 with a Heller hull).

|

|

-

I

lengthened the hull shimming the rear plate by 1.5 mm plastic

sheet. Shaping the shim in place, I realize how much the welding

seams are stepped (they were more flush). Carefully I had to

smooth the welding seams by a cutter and sanding paper. I glued

a spare rear plate from the Heller M4 kit (but any other plastic

piece would be the same) obtaining the extra 2.5 mm needed.

-

Two interlocks were filed for the turret.

-

The rear lifting points, filed away during the sanding job,

were replaced by metallic wire.

-

The telephone box is a bit too tall. I lowered it before gluing

in place.

- The

appliqué armours are well done, but unfortunately I had

to them file away because the hull sides were not parallel and

straight. The sides were slightly curved inside. The difference

was perceptible for the naked eye. After having flattened the

sides the hull resulted slightly slimmer, but still within my

tolerance range.

-

I replaced the appliqué armours with new ones made

by plastic sheet. The right dimensions of the hull plates

can be found here

|

|

-

The transmission cover had some resin excrescences (due to some

cracks in the mould I suppose). To use it I’d re-sculpt

the details. I choose to keep the Italeri one, adding the cast-in

bullet splash and modifying the towing points. The bolt heads

strip was cut off from the Italeri upper hull and glued to

the resin upper hull.

-

The upper hull is missing the sand shield support strip height.

This is visible also on the lower edge of the cast front. The

forward corners cut look small when compared to photos of the

original tanks, with the fixed fenders placed a bit too high.

I filed off the fenders and I restored the hull edge.

-

I replaced the welding seam lines between the cast front and

the welded hull by gluing and sanding down some stretched sprue.

-

I glued a large piece of 1.0 mm plastic sheet with a cut at

the rear. This restored the more correct dimensions, the sand

shields strips and the fixed fenders.

-

Having

corrected the upper hull to attach it to the Italeri hull the

way shown on the instruction didn’t work, so I chose another

method. The lower hull sponson floors were removed cutting horizontally

the wall and the two hull halves now joined well. During this

modify the ejector pin marks were filled and sanded.

-

The

engine deck hinges and bullet splash guards are not symmetrical.

While I kept the hinges as they are, I replaced the bullet splash

with thin plastic strips.

-

The

crew hatches are made in metal. They are not bad, but having

a couple of better Dragon ones from the spare box I preferred

to use these.

|

|

- The

air inlet cover is a metal part. Mine had a hole due to a casting

problem, I filled it. During sanding, I realized the piece also

needed some shape adjustments.

- The

Firefly travel gun lock placed on the engine deck was also used

on the hybrids, but some retained the original one so is important

check the original tank one wants to depict. For mine I used a Dragon

spare one being the kit one missing (anyway in the MR one doesn’t

look well in the photo on the maker site).

- Based

on the photos consulted the trapezoidal stowage bin (for greatcoats

according to the technical drawings) was seldom used so I left it

in the spare box.

- The

missing gun cleaning rods set was replaced by a Dragon spare part.

- I

added the four shackles made by metallic wire.

- I

added to the transmission cover the two track links racks myself

by using six Italeri spare links and plastic sheet. Apparently there

were two layouts: horizontal just below the bullet splash lip (sometime

symmetrically, sometime shifted to the right) or vertical at the

centre.

- Often

forgotten details are the fire extinguishers. I scratchbuilt a couple

with their housings (not so hard to do) and then they were placed

on the engine deck rear corners.

- The

horn and its brush guard were removed on most of the photos I’ve

seen, but its presence is confirmed on some. The tank I'd made didn’t

have it so I left it on the sprue.

- The

engine deck rectangular bin looks a bit short and wider when compared

to the photos I have, so I filed the sides to make it 13 mm wide

(I scaled it from a photo so it could be not exactly correct, but

checking with the crank hole now it look better) and I added a new

cover with plastic sheet.

|

|

| Italeri

lower hull

The

Italeri lower hull needed the following correction of the following

errors:

- The

maintenance belly plates layout was changed by thin plastic sheet.

- The

two transversal rods were replaced by stretched sprue.

|

|

-

The

MR air filters are as good as the Italeri ones. I kept them giving

a more correct position.

-

This time I tried to correct the bogeys height. After having assembled

them with the wheels well glued on, I carefully cut off the arms

with the wheels by a thin sharp blade. I filed off 1.0 mm from

the bogeys bottom and then I glued the bogeys to the hull. For

a better alignment I glued the arms in place at the end. The look

I'd achieve seems more correct in my opinion.

-

My hybrid being a Chrysler tank, I filled the interlock for the

towing hook by a plastic chip.

-

The idlers supports look quite well. The metal pins anyway didn’t

fit well, so I glued them to the idlers on the centred pin side

and filed away the others.

-

The smoke generators are well done and need only to be shimmed

for a better gluing to the hull.

|

|

Wheels

- The

MR wheels are the open spokes type. They are quite well done, although

the holes between the spokes are filled (too deep to depict the

closed welded spokes). I used the Italeri pressed wheels, they aren’t

perfect, but they are the type usually used on the M4 composite/Sherman

hybrid seen in Europe.

- The

MR sprockets are correct for a Chrysler tank, but both had an irregular

sink mark in the centre. Having a couple of sprockets from an Extratech

kit, I used these.

- The

Italeri tracks are the rubber T48 type. I think they are quite well

done (better than others for sure). Being widely used on the Chrysler

hybrid Fireflies I used them. Luckily I had some spare links because

at the end I needed four extra links due to the altered layout of

the set. On the subject of the tracks as far as I can tell, most

of the Firefly hybrids photos I’ve seen show them with the

T48. To choose an aftermarket option I have to say that the remaining

few had the T54E1 type (and two tanks had a T54E1 track on a side

and a T62 track on the other!).

|

|

Conclusion

I have

two opinions about this kit: the first is about the MR Modellbau kit

MR-72022 in general, the second is about this

specific MR Modellbau kit I'd got.

- First

the kit in general: although the hull and turret

small details are very good, these are obscured by the way the hull

rear is cut short. Additionally, I don’t think the turret

layout existed unless a photographic evidence shows up. Other peculiar

pieces need to be corrected or replaced, such as the NWE turret

bin. I suppose MR Modellbau still suggests the Italeri M4A1 as the

base for this conversion because it was the only choice available

when the set was released. However, the newer M4 or M4A1 (Dragon

or Heller) available today would be a better base if MR would adapt

their instructions. Additionally, MR wouldn't have to provide a

number of pieces already present in those plastic kits (such as

the wheel set and the transmission cover) and the modeller shouldn't

have to adapt the Italeri hull.

- On

the subject of my particular kit: the deformation

of both turret and hull sides, the wrong pieces and the missing

ones... I’d like to think this is due to a single unlucky

packaging problem. Anyway this conversion set is not cheap and I

think is a must to find in the box what is advertised.

From

both perspectives my opinion couldn’t be positive.

Thanks to Gianluca Trivero for donating this kit.

This

model can be purchased from

|